SOCIAL – RESPONSIBLE SOURCING

Being Responsible to Forge Sustainable Growth

Material

theme |

Strategic

response |

Impact on

SDGs |

Capitals

Impacted |

| Climate Change & Decarbonisation |

Progressing towards a sustainable future |

|

|

| Water Management |

- Lowering carbon footprint by improving efficiencies, ensuring optimal utilisation of natural resources, increasing the use of renewable energy in operations, growing in a safe & sustainable manner

|

| Diversity, Equal Opportunity & Inclusion |

- Aligned Supplier Code of Conduct to key material issues

|

|

|

| Health, Safety & Well-being |

- Environmental stewardship in supply chain

|

|

|

| Sustainable & Inclusive Supply Chain |

- Promoting use of EVs in procurement

|

|

|

| Labour Practices |

- Business partners' ESG assessment

|

|

|

| Innovation R&D |

- Sustainability assessment (water & biodiversity) for critical business partners

|

|

|

| Human Rights |

|

|

|

| Indigenous People & Cultural Heritage |

|

|

|

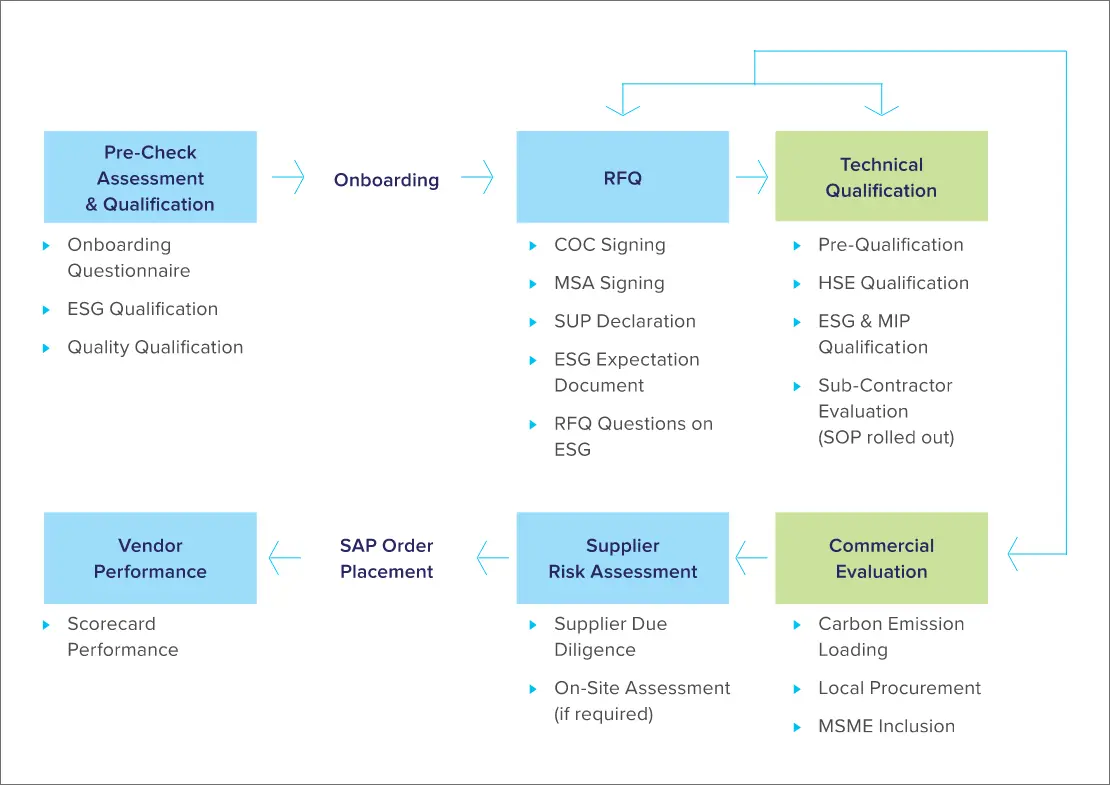

At Hindustan Zinc, we are fully committed to unlocking business values in terms of cost reduction and volume growth through continuous business partner engagement and effective contracting. We remain focussed on achieving our strategic goals through effective market analysis, benchmarking and online price discovery, while building strong relationship with our business partners. Sustainability and ethical business practices are at the core of our business model to ensure long-term success and also to make a positive impact on the societies we serve. In addition, we remain fully focussed on strengthening the foundations of our growth through process automation and quality control. We are moving in the direction of decarbonising our upstream and downstream supply chain now which has the potential to be a major growth driver with our forward-looking vision.

Durairaj M

Chief Commercial Officer

Driven by our strong sustainability focus, we, at Hindustan Zinc, have prioritised responsible sourcing as a key tenet of our business strategy. We have embedded sustainability considerations into our supply chain processes to enhance our performance, and ensure better assessment of risks and opportunities. We collaborate closely with our business partners (BPs) to mitigate supply chain risks and ensure sustainable sourcing. Integration of the environmental, social & governance (ESG) performance of our partners into procurement decisions further nurtures our sustainability ethos. We achieve such integration through a structured framework, supported by various policies, procedures and guidelines such as Supplier Code of Conduct, Sustainable Sourcing Policy, Supplier Sustainability Management Policy and Supply Chain Strategy Document.

ROBUST CODE & POLICY

To ensure responsible and sustainable sourcing, we have put in place a strong Supplier Code of Conduct and a Sustainable Sourcing Policy. Both the documents encapsulate our vision and approach to sustainable sourcing, and outline our efforts to mitigate the health, safety and environment (HSE) related occupational risks. They are crafted to enforce a zero-tolerance policy against human rights violations and promote the adoption of ESG principles among business partners. They also ensure thorough conduct of supply chain risk assessments and skill enhancement, along with transparency in business operations. They cultivate strong and effective relationships with BPs through continuous improvements and digitalisation initiatives.

Stringent Supplier Code of Conduct

The code is required to be stringently complied by all BPs, without exception.

- It primarily addresses key areas, such as labour and human rights, health, safety & environmental sustainability, business integrity, prevention of unethical practices, grievance redressal mechanisms, climate change considerations, legal compliance, zero tolerance towards governance issues, and prohibition of insider trading

- It has been developed through collaboration with customers, BPs, Group companies, and Development Organisations

- It underscores our dedication to uphold internationally recognised standards, including the fundamental conventions outlined by the International Labour Organisation (ILO), the principles of the United Nations Universal Declaration of Human Rights, and prevailing industry norms

- It involves annual assessments of all our BPs in accordance with the code

Strong Transparency Focus

Both the Supplier Code of Conduct and Sustainable Sourcing Policy are driven by our unwavering commitment to ethical governance and transparency.

- Transparency plays a pivotal role in enabling the BPs to identify and address ethical, social and environmental risks within their supply chains

- This facilitates more sustainable and ethical sourcing practices; we consistently maintain compliance and disclosure, in line with internationally recognised standards and frameworks, such as Carbon Disclosure Project (CDP), Global Reporting Initiative (GRI), Task Force on Climate-Related Financial Disclosures (TCFD), Dow Jones Sustainability Indices (DJSI), and others concerning our supply chains

Hindustan Zinc has offered opportunities for learning and bringing new perspectives into my life and work. Participation in Vice Chairman workshops, engagement with top emerging leaders, and involvement in the V-lead initiative have encouraged me to tackle new challenge.

Purva Pancholi Deputy - CCO, Dariba IBU

We have strategically developed our Sustainable Sourcing Policy in conjunction with our Supply Chain Strategy document.

Key Highlights of FY 2023-24

- Formed an alliance to deploy 180 liquified natural gas (LNG) vehicles for inter-unit concentrate movement and finished goods transportation, as part of our supply decarbonisation initiative; successfully deployed 41 LNG vehicles across Hindustan Zinc in the 1st phase

- Forged an alliance to successfully deploy 10 electric vehicle (EV) trucks, with 55 MT capacity each, for inter-unit concentrate movement

- Added 25 BPs under “Use and Pay” initiative for spare part management

- Started using rail transport for coal supply to Dariba mines, to ensure a greener supply chain

- Developed 18 alternate BPs for critical commodities, spares & services, to reduce supply chain disruption

- Collaborated with 25 critical BPs for ESG goal alignment

- Launched supplier portal for ESG self-assessment, along with a video guide on Code of Conduct awareness

- Conducted sustainability assessment (water & biodiversity) for critical BPs

957

Total Commercial BPs transacted

205

Total critical/ significant tier 1 BPs

₹ 9,127 cr

Spent on critical tier 1 BPs

64%

Local spend – state (Rajasthan & Uttarakhand)

FY 2023-24 was a year of innovation in the MSME payment processing system at Hindustan Zinc. As part of our sustained support to the MSME sector, we provide them with business and ensure timely payments. The implementation of the touchless payment feature has further streamlined the process, with Hindustan Zinc reporting an average payment cycle of 35 days in FY 2023-24, which is 22% better than the statutory requirement. We closed the year at a payment cycle of 26 days in March 2024.

As a transitioning military veteran, I've advanced through dynamic roles in Logistics, achieving notable milestones in internal, FG, and acid movements. Hindustan Zinc's dedication to nurturing talent is evident through my award for career advancement via the Ex-Defence Services leadership workshop. Continuing to learn and evolve, I aim to expand my role within the organisation, contributing to its mission of sustainable progress and innovation while also reducing life cycle management costs for HEMM equipment.

Imtiaz Begam Rowther Dy Head - HEMM (Mining Equipment) SCLM - HZL

During my time at Hindustan Zinc, I've consistently grown through various HR flagship programmes. The Company has supported me in all aspects of my life, including balancing my professional and personal responsibilities as a parent to a three-year-old daughter. Hindustan Zinc's flagship diversity programs, including those for LGBTQ inclusion, are excellent. With sustainability as a core vision, at DSC, we ensure 100% responsible sourcing from a commercial standpoint.

Apoorva Vyas CCO - Dariba Smelter Complex

Hindustan Zinc's transparent leadership and unwavering support have fuelled my growth in a positive work environment where I thrive. I'm grateful for the inclusive culture that inspires my best effort daily. Hindustan Zinc's ethical empowerment, pride, and collaboration culture resonates with my values, providing opportunities for growth and cross-functional skill development.

Aditi Rai Chief Commodity & Alternate Fuels, HZL

Transitioning from a 15-year career in the Indian Air Force, I embarked on a new chapter in corporate life, finding purpose at Hindustan Zinc. As a team leader, I achieved significant savings in procurement and streamlined supply chain operations. Through leadership workshops and hiring drives, I've aligned with the company's vision for innovation and diversification, aiming to create safer workplaces.

Richa Varshney Dy Head PSSC, HZL

SUSTAINED BUSINESS PARTNER ENGAGEMENT & PARTNERSHIPS

At Hindustan Zinc, we strive to procure raw materials from BPs who follow sustainable business practices. We partner with BPs who have similar sustainability ethos embedded in their own supply chains as followed by the Company, and whose policies and practices mirror the standards we uphold internally, as part of our efforts to establish a responsible value chain.

- We have introduced ESG expectations in our procurement process via the ARIBA platform

- All our requests for quotation (RFQs) comply with the bidder’s undertaking on waste management rules for prohibition of single-use plastics (SUPs)

- We conducted awareness sessions to facilitate effective communication and promote awareness

- We organised a series of training sessions called "Wednesday for Transition", designed to provide BPs with essential knowledge on ESG topics, including Business Responsibility & Sustainability Reporting (BRSR), climate change risk management, human rights in supply chains, and biodiversity risk & conservation, with active participation from more than 200 participants

These initiatives were aimed at promoting the adoption of best practices in ESG risk management throughout the value chain.

Further to this, we have completed an ESG assessment of our critical value chain partners to evaluate their performance on key ESG criteria, such as greenhouse gas (GHG) emissions, water conservation, Modern Slavery Act in the supply chain, etc. Following this, we have engaged with their teams to align with our long-term ESG objectives and communicate our expectations.

BPs who may not meet Hindustan Zinc’s ESG expectations can refer to the Company’s Business Partner Information Portal for guidance on meeting our expectations and aligning their practices accordingly. The portal offers a resource for Hindustan Zinc’s expectations and provides its own best ESG practices for reference.

“NO” TO SINGLE-USE PLASTIC IN SUPPLY CHAIN

Our goal is to eliminate the use of single-use plastic items within our premises, aligning with the latest Plastic Waste Management (Amendment) Rules, 2021 set forth by the Ministry of Environment, Forest and Climate Change (MoEF&CC). This initiative targets zero usage of single-use plastics across our entire value chain.

We have prohibited both single-use plastic items and the use of plastic bags with a thickness of less than 100 microns from FY 2021-22 onwards, and we continue to ensure strict compliance with the same. All our BPs are required to share an undertaking acknowledging their responsibility towards Hindustan Zinc’s ESG commitments with ‘no usage of single-use plastics’ during packaging as a part of the tendering process. As an alternative, biodegradable packaging or use of plastic complying with established rules is preferred across the supply chain.

ENVIRONMENT STEWARDSHIP IN SUPPLY CHAIN

We have embraced environmental stewardship as a core belief guiding our actions. We ensure sourcing of products and materials in a manner that minimises our environmental footprint and promotes sustainability.

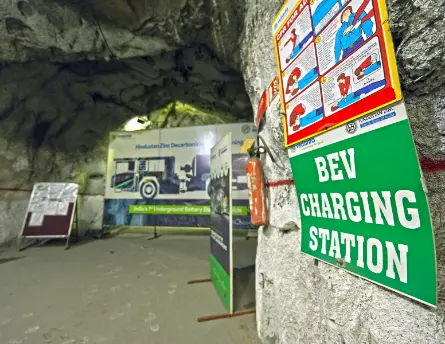

Transition towards battery electric vehicles (BEVs)

- Introduced BEVs for our underground mining operations and BEV material handling equipment across our smelters, in line with our goal to reduce our carbon footprint through responsible sourcing initiatives

- Aim to convert 50% of our equipment fleet to EVs by 2030

100% greener fuels in logistics

- Transitioning all our inter-unit transport (IUT) & finished goods (FG) movement to 100% greener fuels in logistics, with EV and LNG vehicles

Alternative product development

- Shifted to a non-toxic, eco-friendly alternative from highly toxic materials to reduce iron impurity content in our flotation process at mills

- Resulted in substantial savings in inventory expenses as the new product is cost effective

- Led to the reduction of our environmental impact and improved safety for our employees and communities

- Reduced reliance on imports, simplifying logistics and cutting international procurement costs

Product-level life cycle assessment

- Comprehensive strategy and tools developed for product-level life cycle assessment for our critical machines & commodities

- Started systematic collection of data from BPs to determine the Scope 3 GHG emissions brought to our supply chain through procurement of certain goods, as well as the associated economic cost

- Aimed at significant reduction in our Scope 3 emissions

- Conducted training sessions for internal procurement teams and critical material BPs to facilitate the implementation of life cycle assessment within our procurement process

Once the process is streamlined, we will factor in the carbon cost of procuring these supply items when making procurement decisions.

TRANSPARENT BP IDENTIFICATION, ESG ASSESSMENT & SCREENING

1

Identification of potential BPs

- Market research

- Consultation

- Expression of interest (EOI)

- Online searches

- Direct outreach

2

Screening

- ESG, quality & business relevance

3

Risks considered during BP screening

- Country-specific

- Sector-specific

- Commodity-specific

4

BP evaluation and registration

- Registration questionnaire

- Evaluation & approval by designated authorities

- Commitment to ESG criteria

- ARIBA supplier lifecycle and performance (SLP) module

5

Pre-qualification questionnaire for screening BPs

- ESG & HSE questionnaire based on international standards

- Meticulous evaluation to ensure BPs meet our standards, including HSE criteria

- Partners scoring at least 75% to upload all necessary documents, including technical and commercial qualifications, on ARIBA portal for verification

6

Performance assessment

- Against compliance and ESG criteria

- BP payments linked to adherence with safety and statutory obligations

- Penalty/incentive system in place to enhance productivity and safety across all locations

7

Regular monitoring for key contracts

- Covers safety, human rights and environmental compliance

- Includes data monitoring on GHGs, water, climate & water risks, etc.

8

Regular contractor field safety audits (CFSAs)

- For on-site service contractors to promote health, safety, environment & social (HSES) governance practices

9

Integrated performance module in ARIBA

- Tracking of BP performance on quality and delivery

- Corrective action, if necessary

SUPPLY CHAIN RISK ASSESSMENT & MITIGATION

- Three-level Assessment: Desktop-based assessment conducted every 3 years for all BPs, second party assessment for critical BPs, third-party assessment for sustainability high-risk BPs

- Assessment of BPs is based on international standards and methodologies such as LME responsible supply chain guidance, Modern Slavery Act, SMETA (Sedex Members Ethical Trade Audit), Responsible Minerals Initiative, or others

- Effective due diligence and risk management practices implemented for mitigating conflict affected and highrisk areas (CAHRA) related supply chain risks and promoting responsible sourcing practices

- Pre-defined criteria for identifying critical BPs and service providers, to address inbound supply chain risks

- Effective internal management practices established for due diligence, to identify, assess and manage potential risks associated with mineral supply chains

- Process in place to identify and report red flags, along with results of risk assessments, to senior management; covering risks related to serious human rights abuses, use of public or private security forces, support to non-state armed groups, money laundering, tax evasion, bribery, and misrepresentation of material origin

- Annual due diligence assessments & sustainability questionnaires for BPs by independent third parties, along with on-site evaluations, as needed, to assess quality practices, ESG initiatives and HSE practices

DIGITALISING TO STRENGTHEN SUPPLY CHAIN

BP grievance mechanism

- Grievance portal integrated into a mobile app, ensuring prompt, efficient and effective redressal of grievances of BPs

- Grievance committee set up with pre-defined escalation procedures to ensure prompt tracking and redressal of grievances, through automated emails and updates

Vendor zone, information portal and e-learning training module on ARIBA network

- Available on our website at https://www.hzlindia.com/vendor/, to guide new BPs

- Easy-to-follow video guides available on the BP training e-module to create awareness of our Code of Conduct, ESG expectations, and various processes, such as auctions, invoice creation, supplier profile management, etc.

ARIBA SLP

- Streamlined our procurement operations, ensuring transparency, compliance and efficiency

- Automation of BP management processes and centralisation of information, helping us engage with qualified BPs, mitigate risks, and drive continuous improvement in supplier relationships

We recognise the importance of leveraging digital technologies to drive efficiency, transparency, and environmental stewardship across our supply chain. As part of our digital transformation agenda, we have embarked on a journey to revolutionise our end-toend procurement processes by embracing paperless request for proposals (RFPs) to touchless payment. The introduction of paperless RFPs has enabled Hindustan Zinc to accelerate the procurement cycle, from the stage of creation of RFP documents to BP selection and contract negotiation.

We successfully avoided approximately 1.07 million pieces of paper in FY 2023-24 with the implementation of the SAP Business Network, which facilitated electronic transactions. Our digital platforms are helping in realtime collaboration, document sharing, and electronic signatures, reducing manual effort and speeding up decision-making processes. The use of the latest digital technologies on our platform has positively impacted 11 of the 17 UN Sustainable Development Goals.

RESPONSIBLE SOURCING GOVERNANCE

Our multi-tier sourcing governance structure is aligned to ISO 20400. This involves integrating frameworks and providing training to internal stakeholders to enhance their competency in sustainable sourcing practices. During FY 2023-24, we conducted a full-day training session, with the support of a third-party certification company, to acquaint participants with ISO 20400 requirements, backed by simple BP evaluation

FORGING AHEAD STRATEGICALLY

Our focus, going forward, will be on:

- Establishing and executing a sustainable supply chain methodology, aimed at fostering deeper engagement with BPs on ESG. It involves conducting risk assessments, mapping materiality, evaluating compliance with the Modern Slavery Act (MSA), implementing corrective measures, and crafting an engagement plan to address any identified issues

- Conducting third-party audits, aligned with international frameworks to evaluate BP performance across ESG pillars

- Recognising and awarding BPs who demonstrate excellence in ESG parameters, with established ESG practices in place

- Implementing a BP feedback mechanism to identify and address gaps for continuous improvement

- Implementing local/preferential procurement policies, engaging local BPs, and partnering with Indian associations to identify potential local partners

- Creating a supplier best practice database to facilitate collaboration and support the growth of BPs

- Implementing memorandum of understanding (MoU) with critical BPs to formalise agreements and align them with the Company on shared objectives

CASE STUDY

Decarbonising our logistics

As a sustainability-focussed organisation, we are continuously exploring ways to reduce our carbon footprint across our business operations. To decarbonise our logistics operation, we have adopted various measures to reduce its ecological impact and de-risk the supply chain from emerging regulatory and other climate change risks.

During FY 2023-24, we deployed 10 electric vehicle (EV) trucks and 41 liquefied natural gas (LNG) trucks through a strategic partnership with a business partner. These trucks, of 55-tonne capacity each, ensure uninterrupted operation, while ensuring the required infrastructure for charging the EV fleet along with LNG station.

The deployment of these vehicles will propel us further towards achieving our net zero goal and establishing a standard for responsible mining practices.

Key features

- Long-term contracting for 10 years & 5 years for EV and LNG fleet, respectively

- Enhancing the reliability of transport movement

- Incorporating additional safety features to reduce incidents

- Ergonomically designed driver cabin to provide additional comfort with fatigue management

Key outcomes

- c.100% carbon emission reduction on EV fleets

- c.30% carbon emission saving in LNG fleets

- 7% reduction in operational cost with respect to fossil fuel fleets

CASE STUDY

Boosting Efficiencies with Centralised Warehousing System

Hindustan Zinc identified challenges in its supply chain operations, including decentralised sourcing and warehousing for spare parts procurement, which led to inefficiencies, higher costs, and discrepancies in order fulfilment. To address these challenges, we implemented centralised supply chain solutions, comprising centralised sourcing and warehousing, in 2021, translating into important benefits for the Company during FY 2023-24.

Key features

- Partnered with TVS Supply Chain Solutions to establish a 4PL (4th party logistics) warehousing system, with the aim to streamline processes and achieve cost savings through a “Use & Pay” model

- Made efforts to standardise spare parts across business units, and transition inventory from unit stores to centralised warehouses

- Undertook automation projects to enhance system efficiency and transparency, including real-time GPS tracking for vehicles, bar code scanner-based material movement, and electronic proof of delivery (e-POD) through web and mobile applications

Key outcomes

- Improved stock transparency, enhanced order accuracy and robust transportation

- Reduced plant breakdowns, reduced manpower and operating costs, minimised freight expenses, and heightened customer satisfaction

- Achieved impressive inbound and outbound order fulfilment metrics, with 98% of inbound turnaround time within 24 hours and 97% of outbound orders served within 48 hours

- Substantial operational cost savings of ₹ 85.65 lakhs per annum

A workshop on spares supply chain management was organised at a third-party mega warehouse that covered key aspects such as inventory management and storage, demand forecasting quality improvement, and the use of technology for efficient tracking and procurement.

CASE STUDY

Enhancing Mining Equipment Life with Full Machine Rebuild

The mining equipment at Hindustan Zinc had a medium lifespan, resulting in higher capital expenditure (capex) on account of purchase of new machineries due to excessive equipment deterioration. To enhance the life of heavy earth moving machines (HEMMs) and lowprofile dump trucks (LPDTs), we initiated a rebuilding project during the year. The project was aimed at achieving additional life of 20,000 hours (equivalent to 5years) post rebuild, resulting in capex deferment for the same period.

Key features

- Involved full machine rebuild project, with extended scope of work, including power train replacement, overhaul with software testing, and updates with warranty

- Pilot project undertaken for 5 machines, to be replicated to other equipment post successful implementation

Key outcome

- Machine condition restored to new-like, with new product identification number and service meter unit (SMU) starting from zero

- Achieved certified powertrain, commercial engine, hydraulic and machine component rebuilds, cab overhaul, work implement overhaul, software testing and painting

- Improved availability and lowered operational cost

- ₹ 7.81 crore saving achieved per equipment

- Engineering updates made to the latest available options

- Total economic life extended to c.12 years, translating into 71% additional life with investment of 47% of new equipment cost

- 1.5 months payback against capex of new equipment

PRE & POST REBUILD

Before Rebuild: Availability - 77%

After Rebuild: Availability - 88%

Working with Hindustan Zinc Limited has been an exceptional experience. Your commitment towards innovation, exemplified by the introduction of 1st Battery Electric Vehicle (BEV), has significantly enhanced safety & quality standards setting up a new benchmark in UG space of operation. HZL’s dedication to sustainability & quality align perfectly with our values. Their proactive approach and relentless pursuit of excellence have consistently delivered outstanding results, solidifying our partnership as one built on trust, reliability, and mutual growth

Subhasis Mohanty Vice President & Managing Director Normet India Pvt. Ltd.

Epiroc greatly appreciates the continued long and strong partnership we have with HZL. We are thankful for the open and transparent discussions with mutual respect we have with the commercial team enabling us to find a win-win solution which is key for any business relationship. We always admire the in-depth, fact-based analysis your team does, which keeps us on our toes but also enables us to do our best. Thank you for the continued patronage of Epiroc products enabling us to be your sustainability & productivity partner.

G Arunkumar President - India

Epiroc

As a premier mining equipment solutions provider, Sandvik has forged a robust partnership with Hindustan Zinc Limited, spanning a remarkable 15 years.

We remain steadfast in our commitment to becoming their preferred primary ally, providing pioneering solutions such as digital transformation, automation and electrified equipment to support their sustainability and decarbonisation goals in mine operations. These efforts not only advance their growth trajectory but also align with both our organisations’ broader objective of creating future-ready mines.

Together, we are poised to redefine industry standards and lead the charge towards a brighter, more sustainable future.

Manojit Haldar Managing Director and President Sales Area India Sandvik Mining and Rock Technology India Pvt Ltd