| Material theme |

Strategic response |

SDGs impacted |

Capitals Impacted |

Sustainability Goals 2025 |

|---|---|---|---|---|

| Health, Safety & Well-being |

S5 - Progressing Towards a Sustainable Future | Human Capital |

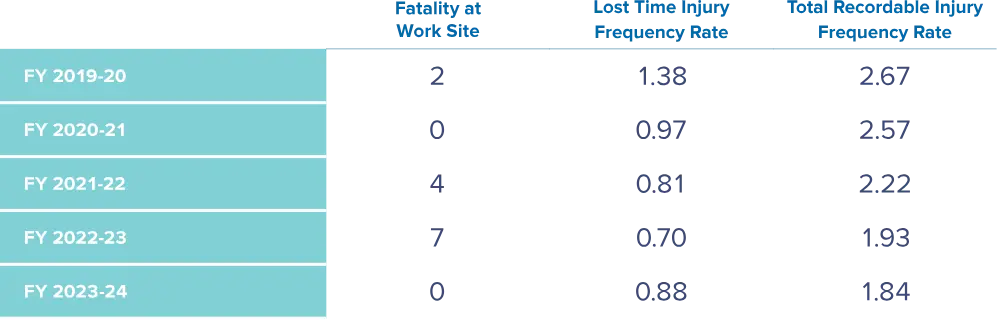

Zero work-related fatalities and 50% reduction in total recordable injury frequency rate (TRIFR) |

Hindustan Zinc is committed to achieving excellence in Health and Safety (H&S) management. Our goal is to ensure zero harm for all our stakeholders by eliminating unsafe work conditions either on-site or off-site.

Stringent compliance with the highest standards of Health, Safety and Environment (HSE) for our people and the society at large is a key strategic priority for us, at Hindustan Zinc. Forging responsibly ahead, we have made significant progress in our safety excellence journey - ‘Aarohan’, and will continue to strengthen the excellence parameters that are ingrained in it.

Our strategic priorities are crafted to strengthen these pillars to achieve our 2025 sustainability goals.

Achieve zero fatality

Achieve zero cases of occupational illness

Improve occupational health and hygiene

Critical risk management

Critical review of the Vedanta Sustainability Assurance Programme (VSAP) audit process

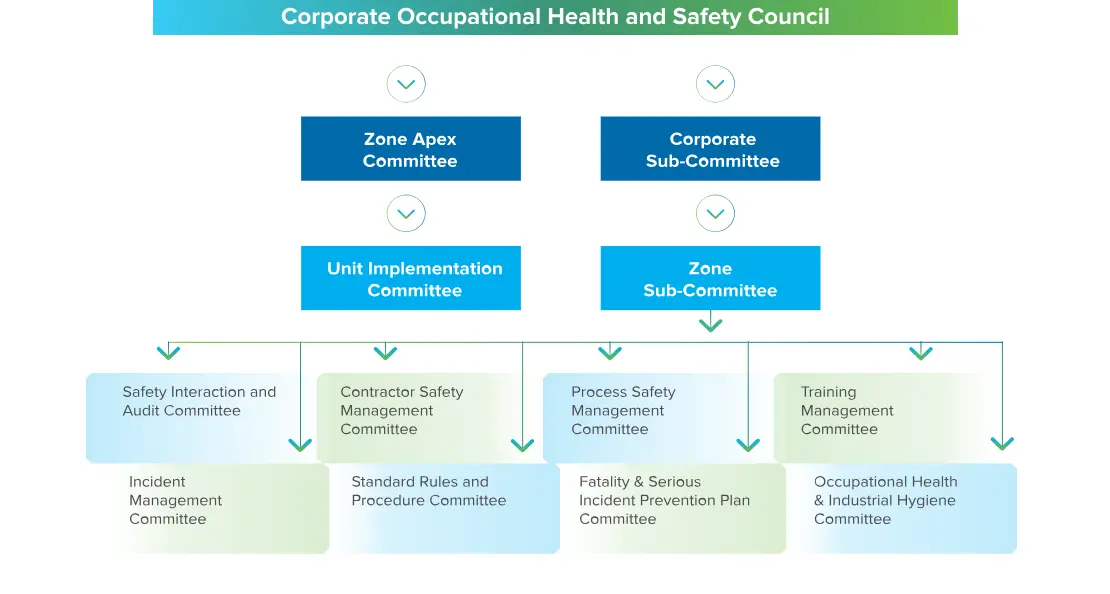

We have in place a robust governance structure to steer our safety excellence journey ‘Aarohan’, on which we have been moving forward since 2013. We are continuously nurturing and reinforcing this structure through strategic initiatives.

Visible Felt Leadership

Right MIP in place

Tracking of critical barriers through Fatal and Serious Injury Prevention Programme and Critical Risk Management

Focus on process safety management

Increased employee engagement

Standardisation of safety systems

Competency development and skill enhancement

Automation and Innovation

Enhanced Risk Perception

Our safety governance structure is driven by the corporate occupational health and safety council, which guides the safety management system at Hindustan Zinc.

From coordinating VSAP audits to leading safety calls and engaging with senior leaders, I've embraced growth opportunities. Recognition, like receiving the Sword of Honour and being named star performer, fuels my dedication. Hindustan Zinc's training initiatives, including ISO 45001 Lead Auditor courses, fostered my professional development profoundly.

Leading the digitisation of our Safety Management System, I improved processes and data accuracy, creating a safer work environment. With unwavering support from the Company, I've excelled in an innovative, collaborative culture. Hindustan Zinc prioritises safety through investments in employee competency, advanced equipment, and sustainable practices, and I look forward to further growth within the organisation.

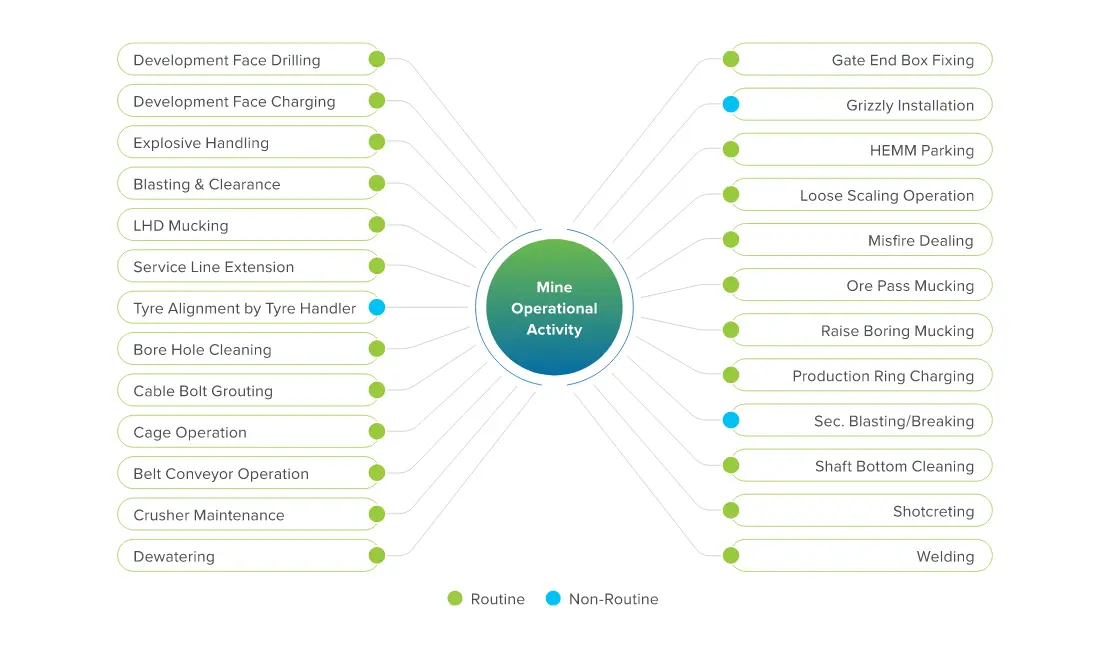

(25 Routine and Non-Routine Activities) 23,460 inspections during the year

(11 Identified Risks - 252,747 critical control verifications during the year)

(Fatality CAPA Closure – 96%)

(11 Risks)

(6 Safety Pauses conducted across the Company)

During the year, we strengthened our safety proposition manifold through several impactful initiatives.

The development of a robust integrated structural stability programme across the organisation was a significant milestone during the year in our journey towards zero fatalities. We have put in place a structure integrity management community, chaired by our Deputy CEO.

Hindustan Zinc has always pursued world-class practices for improving the safety of its assets and facilities through the journey of continuous improvement. To strengthen our focus on the integrity of the structures, we have in place the structure integrity management community to work towards predictive assessment and corrosion mapping. It will also manage risks through timely rectification of old, damaged and corroded structures in the plant, ensuring safe and reliable operations.

The Company’s smelters have 21 sulphuric acid bulk storage tanks. For assessing and ensuring the integrity of these tanks, a third-party thickness inspection is conducted every six months. We have completed residual life assessment phase 1 study of all acid tanks across locations.

Asset integrity/structural stability works carried out across Hindustan Zinc in FY 2023-24

This inspection includes external visual inspection, magnetic particle testing, dye penetrant test, ultrasonic thickness measurement, time-of-flight diffraction (TOFD) scanning, hardness test and visual inspection.

A vital aspect of ensuring safety relates to awareness and attitude. It is important for all those associated with Hindustan Zinc to be cognisant of the critical risks, and to be imbued with an attitude that is focussed on observing safety. Our critical risk management programme – Vihan, is aimed at enlightening everyone in the organisation about all critical risks. It draws inspiration from the Sanskrit word for dawn, Vihan - the harbinger of light. The key facets of the programme are identification of the early warning signs and implementation of critical controls.

Strong controls are in place across all the business units at Hindustan Zinc for the following critical risks:

The above-mentioned four risks were rolled out in FY 2022-23, in alignment with the Company’s mission of zero harm. For managing the critical risks associated with our operation and for fatality elimination, we launched seven more risks across all business units of Hindustan Zinc during FY 2023-24. These are:

Vihan has enabled us to ensure close monitoring of all the identified critical controls, and installation of proper systems to implement the same. During the year, we implemented Critical Risk Management through 'Enablon', integrating all critical control checks to centrally monitor and take necessary actions.

A key safety initiative of FY 2023-24 was the launch of Infrastructure matrix across the Company. This is a consolidated matrix developed by a group of subject matter experts after a series of risk workshops. The initiative is in line with our vision of ‘Zero Harm’ and seeks to prevent reoccurrence of similar fatalities within the Group. It helps to eliminate the probability of occurrence of fatalities for the identified critical risks among the Group businesses, by improving the infrastructure of various risks.

In a momentous step towards enhancing the safety and well-being of our people, we have introduced 'SURAKSHA KAVACH' - Phase I of the Fatality Prevention Controls initiative for our underground mining operations. In Phase I, the initiative is designed to proactively address potential risks associated with 25 diverse activities, both routine and non-routine, conducted in our underground mining operations. It outlines clear NO-GO criteria and critical checks that must be meticulously conducted by our statutory supervisors and competent personnel, including mining mates, foremen and operators, before the commencement of any of these activities.

‘SURAKSHA KAVACH’ goes beyond CRM, which is a riskspecific initiative that focusses on the top risks that exist within our business. We have identified critical controls associated with each risk, and ensure that these controls are in place while carrying out the job. We drive CRM through the critical control verification checklist, and we ensure we have developed a governance structure for each risk, with well-defined frequency for carrying out the inspection.

‘SURAKSHA KAVACH’, on the other hand, is an activity based risk control programme, aimed at ensuring that all the activities (both routine and non-routine) take place safely. This programme acts as a catalyst in our risk management approach. It helps us ensure that all basic and critical requirements are available and complied, with respect to the developed safe operating procedures while performing the activity. This is a risk management process that is being driven by end users.

We conducted safety pause across all our operational units during the year, with the theme ‘stop work if it’s not safe’. During this connect, all recent safety incidents in the Group were discussed and key learnings were shared. The programme was organised by business partners in all the three shifts, including the night shift.

To spread a positive message on safety among the masses

Serious incidents/fatalities to be discussed along with other Group entities, and positive learnings to be shared

A 10-day capacity building training programme on disaster management emergency response was conducted by National Disaster Response Force (NDRF) at Dariba Smelting Complex.

Ensuring the safety and reliability of a winder system is vital in the industries where it is used. However, detection of a broken strand of the headrope within the winder system is often overlooked, even though the headrope is an essential component. An undetected breakage in a strand of the headrope, which is responsible for bearing the load during hoisting operations, can lead to catastrophic consequences, such as equipment damage, injuries, or even fatalities. It is vital, therefore, to have in place robust methods to detect a broken strand of the headrope to ensure operational safety and prevent potential mishaps.

Our innovative solution helps in the quick identification of broken headrope strands in the winder system at Rampura Agucha Mine (RAM).

The flammable hydrogen gas in the leaching area is a potential safety hazard as it can ignite and trigger a fire. To address this safety concern, we have implemented an online monitoring system for hydrogen concentration range at the Dariba Smelting Complex (DSC). The initiative is guided by the key performance indicator (KPI) of achieving zero fire incidents due to hydrogen ignition.

As part of our sustained efforts to ensure employee safety, we continue to invest in effective occupational health management across the organisation. Our efforts are focussed on boosting retention and reducing absenteeism to boost productivity. Fostering a healthier lifestyle among our people is key to this strategy, which covers lifestyle management training backed by advanced technologies.

Cases of occupational health illness

Medical Examinations (initial and periodical) conducted

(During FY 2023-24)

At Hindustan Zinc, we have taken significant strides in prioritising the mental health and overall well-being of our employees and their family members through the Employee Well-being & Assistance Programme (EWAP). The services under EWAP are not only available to the employees but also extend to three dependents, offering a comprehensive support system.

Going forward, we are committed to further strengthening our employee well-being initiatives, ensuring a healthy and supportive environment for all.

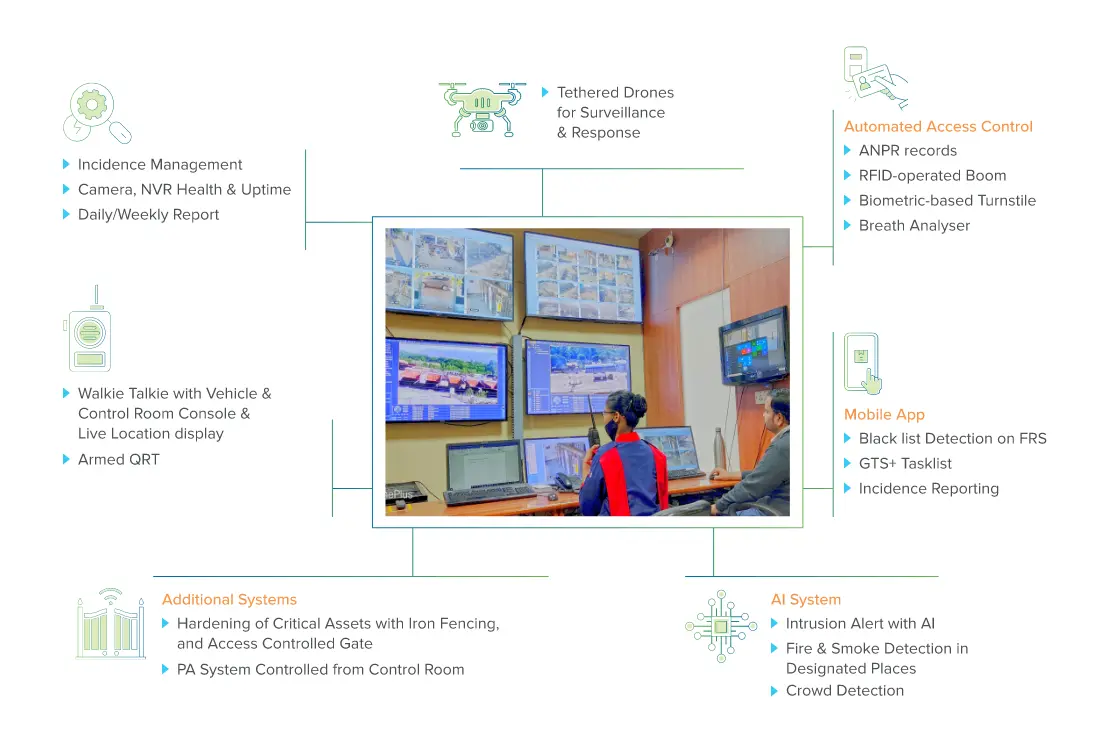

At Hindustan Zinc, we are cognisant of the critical importance of strong physical security measures for safeguarding our operations, employees and assets. With a strong focus on insulating our business operations from security risks, we have in place a robust security function, which we are continually strengthening through strategic investments. We ensure strict compliances to regulatory and other norms, adherence to safety processes, and development of physical security best practices and guidelines to provide the Company with a competitive advantage in the continuously transforming business landscape. We also collaborate closely with our stakeholders to reinforce our physical security edge.

Our physical security function is:

We have been progressively augmenting our security capabilities through a series of targeted measures, which include:

We have developed a synergised, lean, hybrid, engaged and highly skilled security team, with a focus on optimal cost and higher productivity. The team is aligned with the Company’s thrust on promoting gender diversity, with 35% gender diversity among our security leaders. Our business partner security team comprises 4 transgenders and has 3/4th ex-servicemen.

In collaboration with Rashtriya Raksha University, a central university and an institution of national importance under the aegis of the Ministry of Home Affairs, Government of India, Hindustan Zinc has been organising customised certified courses and training programmes for its security team. These initiatives are tailored to address identified specific training needs, empowering our security personnel with the skills and knowledge needed to effectively mitigate security risks.

We have been organising certified Master Trainers' Training courses for our officers through our partnership with the National Disaster Response Force (NDRF) under the Ministry of Home Affairs, Government of India. These trained officers serve as first responders, and play a vital role in training the shop floor personnel on emergency management, particularly during disasters. This helps in safeguarding human lives and assets during the golden hour.

Our physical security function is driven by our commitment to the pursuance of sustainable practices in security management. As part of the Group’s commitment to comply with the guidelines and objectives of Voluntary Principles on Security and Human Rights (VPSHR), Hindustan Zinc has been imparting training to all security personnel on human rights compliance. We are fully compliant to the key performance indicators (KPIs) of the Voluntary Principles initiative. Vedanta Group has already applied for membership of VPSHR, and Hindustan Zinc too is part of the initiative.

Hindustan Zinc has adopted a proactive approach to security management by implementing the convergence of physical security with information technology (IT), on a Build-Own-Operate-Transfer (BOOT) model in collaboration with its security business partners. This innovative approach enables real-time alerts on identified security breaches and structured response capabilities, enhancing our ability to thwart crime attempts effectively. Our process-driven and audited security systems management has facilitated the implementation of the first-ever end-to-end security management in our kind of industry in India. This initiative has augmented detection and response capabilities of our security systems management, while optimising security manpower deployment and cost.