BUSINESS SNAPSHOT

Powered by Integrated Operations and Robust Portfolio

Our operations are driven by the synergistic integration of various processes spread across:

Smelters & Refineries

(Hydrometallurgical Zinc Smelters, Lead Smelters, Pyrometallurgical Zinc-Lead Smelters)

Captive Power Plants (CPPs)

Our strategic focus in these processes remains on boosting operational efficiencies and productivity, enabling innovation and safety, and ensuring responsible business operations.

OUR OPERATIONAL SEGMENTS AT A GLANCE

EXPLORATION (MINERAL RESOURCES AND ORE RESERVES)

- Strong technology and innovation edge

- Long mine life of 25+ years

- Continuous delineation and upgradation activities

- Focus on enhancing R&R base to over 500 Mt and reserves to 200 Mt

MINES

- Strategic locations in the ore-rich state of Rajasthan (Rampura Agucha, Sindesar Khurd, Rajpura Dariba, Zawar and Kayad)

- Globally benchmarked operations supported by high safety standards and trained workforce

- Superior and sustainable practices

- Enduring focus on operational efficiencies and cost optimisation

- Volume growth driven by sustained underground operations

SMELTERS & REFINERIES

- Strategically located smelters in Chanderiya, Dariba and Debari in Rajasthan, in proximity to the mines

- Zinc-Lead-Silver metal refineries ideally located at Pantnagar in Uttarakhand

- Fully integrated operations, aided by captive power

- Continual efforts to debottleneck the smelters, expand the value-added product portfolio, and recycle/ reuse the waste generated in the operations

CAPTIVE POWER PLANTS (CPPs)

603.16 MW

Total captive capacity

- Captive thermal, solar and waste heat recovery power plants

- Providing low-cost and reliable power for the Company’s sustained operations

- Augmentation of solar power capacity to push climate change goals

- 450 MW renewable power delivery agreement for power cost insulation from commodity price variations

- Boosting thermal power capacity (more energy from same amount of fuel) through innovation

OUR PRODUCTS AND APPLICATIONS

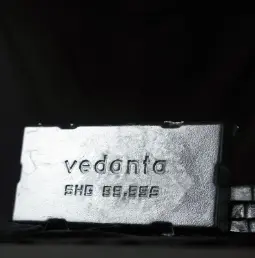

REFINED ZINC

APPLICATIONS

- Roadways and bridges

- Power generation and transmission

- Renewable energy

- Construction

- Railway infrastructure

- Automotive

- Chemicals

- Telecom towers

VALUE-ADDED PRODUCTS

- Continuous Galvanising Grade

- Die-cast alloys

- SHG & HG Jumbos

- Zn Dust

MAJOR KPIs

817 kt

Production Volume

₹ 18,061 crore

Revenue

REFINED LEAD

APPLICATIONS

- Lead Acid batteries

- Construction

- Defence Applications

- Electrical Cables

MAJOR KPIs

216 kt

Production Volume

₹ 4,076 crore

Revenue

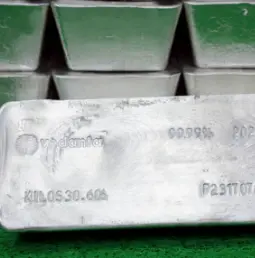

REFINED SILVER*

APPLICATIONS

- Jewellery

- Tableware

- Electrical contacts

- Investment

- Solar photovoltaic panels

VALUE-ADDED PRODUCTS

- Mini (1 kg) bars

- Silver powder

MAJOR KPIs

746 MT

Production Volume

₹ 5,368 crore

Revenue

*silver is a by-product of our smelting process